Hose failures can result in safety hazards, unplanned downtime, and expensive repairs. Understanding the most common causes can save your operation time and money.

Top Causes of Hose Failure & How to Avoid Them

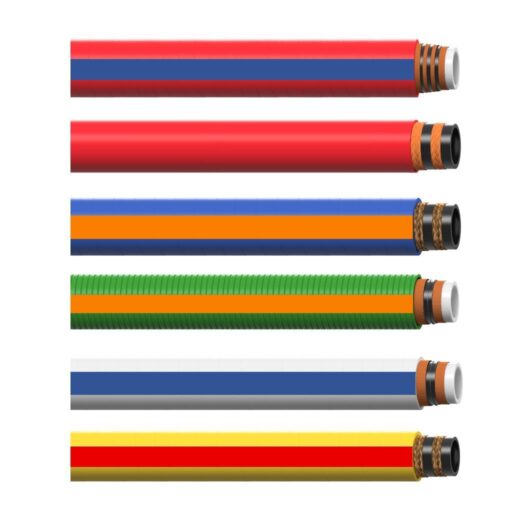

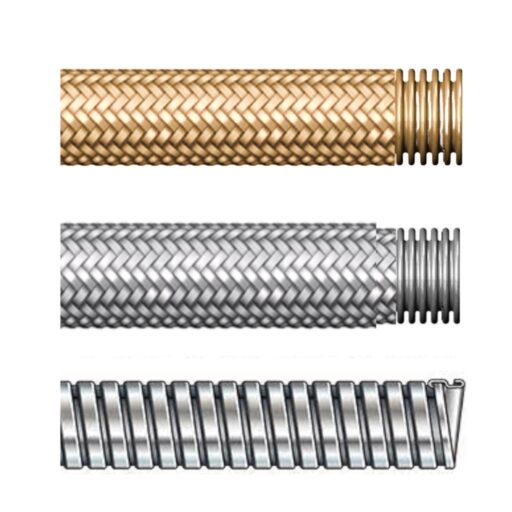

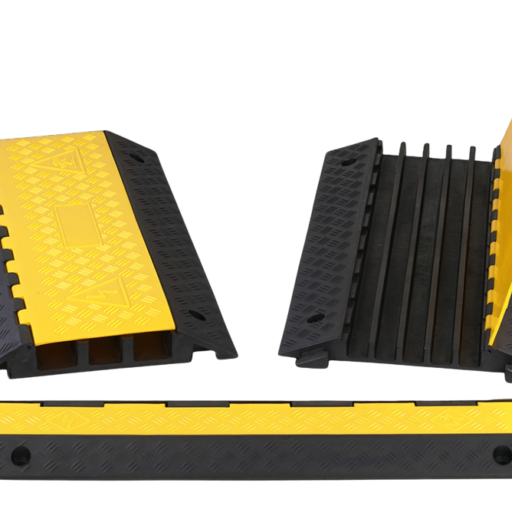

Abrasion & External Damage – Hoses rubbing against rough surfaces wear down quickly.

🔹 Solution: Use protective sleeves and reroute hoses away from abrasive areas.

Improper Bend Radius – Over-bending restricts flow and weakens the hose.

🔹 Solution: Follow manufacturer bend radius guidelines and use supports.

Extreme Temperatures – Heat and UV exposure degrade hose materials.

🔹 Solution: Use heat shields and proper storage methods.

Pressure Surges & Overloading – Spikes beyond rated pressure can cause sudden failure.

🔹 Solution: Install pressure regulators and select hoses with appropriate ratings.

Chemical Incompatibility – Incorrect hose selection can lead to material breakdown.

🔹 Solution: Verify chemical compatibility before installation.

Prevent Hose Failures with Proactive Maintenance

✔ Perform routine inspections – Check for cracks, kinks, and leaks.

✔ Pressure test hoses regularly – Identify weaknesses before failure occurs.

✔ Replace worn hoses before they fail – Prevention is always cheaper than emergency repairs.

Need a Hose Failure Analysis?

Shipyard Supply specializes in hose failure assessments and preventive maintenance plans. Contact us today to improve safety and reliability in your operations.