Crimping vs. Banding Industrial Hoses: Key Factors to Consider

When assembling industrial hoses, one of the most critical decisions is whether to crimp or band the hose fittings. The right choice depends on factors such as pressure requirements, hose type, application environment, and long-term durability. Below, we explore the key considerations and answer common FAQs to help you make an informed decision.

What Is the Difference Between Crimping and Banding?

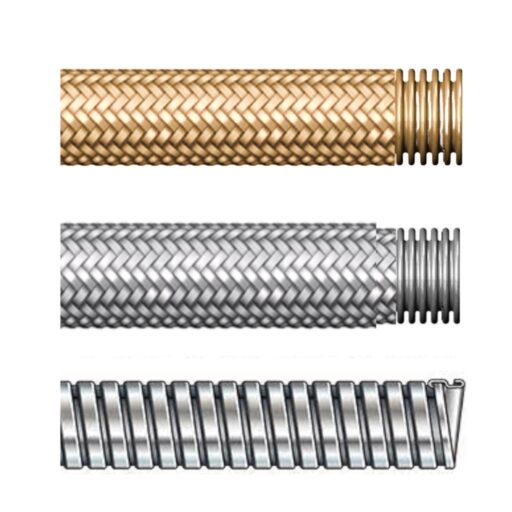

Crimping involves using a hydraulic press to compress a metal ferrule around the hose and fitting, creating a permanent, secure seal.

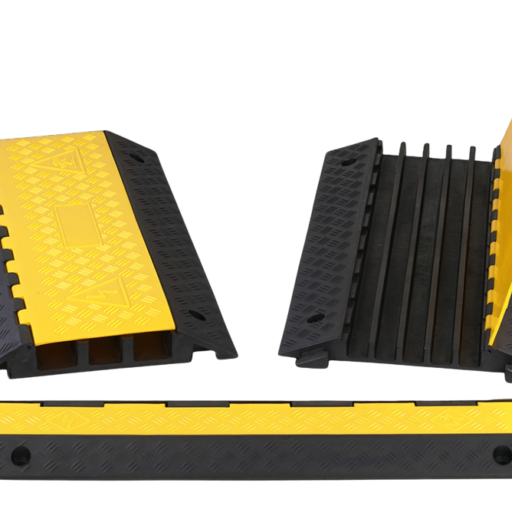

Banding uses clamps or bands to secure the fitting to the hose, often with multiple bands for added retention.

Factors to Consider When Choosing Between Crimping and Banding

- Pressure Rating

Crimping: Provides a higher-pressure rating and ensures a more consistent seal.

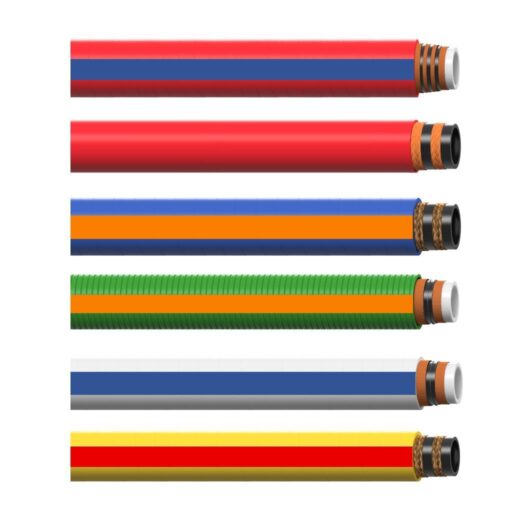

Banding: Suitable for lower-pressure applications but may not hold up under extreme pressure fluctuations. - Hose Type and Material

Crimping: Recommended for hydraulic, chemical, and steam hoses where precision and strength are required.

Banding: Often used for suction, discharge, and general-purpose hoses with lower-pressure requirements. - Application Environment

Crimping: Ideal for harsh environments with exposure to chemicals, abrasion, and high temperatures.

Banding: Best suited for temporary applications or situations where quick repairs may be needed. - Longevity and Reliability

Crimped hoses tend to have a longer service life due to their strong, uniform attachment.

Banded hoses require periodic inspection and may need tightening or replacing over time. - Installation and Maintenance

Crimping: Requires specialized equipment but offers a one-time, secure solution.

Banding: Can be done on-site with minimal tools, making it useful for field repairs and quick replacements.

Top 3 FAQs About Crimping vs. Banding Industrial Hoses

Which method is better for high-pressure applications?

Crimping is preferred since it provides a stronger, more secure connection withstanding higher pressures.

Is banding a reliable option for industrial hoses?

Banding can be reliable for low-pressure applications, but it may not hold up well in high-pressure or critical environments.

Can I switch from banding to crimping?

Yes, many applications transition from banding to crimping to improve durability, safety, and reliability.

Choosing between crimping and banding depends on the specific needs of your hose application. Crimping is the best choice for high-pressure, long-term, and high-reliability applications, while banding remains useful for temporary setups, suction hoses, and field repairs. Understanding these factors will help ensure the best performance and longevity of your industrial hose assemblies. If you have questions, call an expert at Shipyard Supply today.