Largebore Hose Production Services

At Shipyard Supply Inc., we offer industry-leading large-bore hose crimping capabilities, ensuring we can meet your high-volume hose fabrication needs with precision, efficiency, and reliability. Our advanced crimping equipment can handle hoses up to 16 inches in diameter, making us a trusted provider for heavy-duty industrial applications. With the capacity to produce dozens of custom-fabricated hoses per day, we are equipped to handle both high-volume production runs and urgent one-off requests with rapid turnaround times of hundereds of hoses per day.

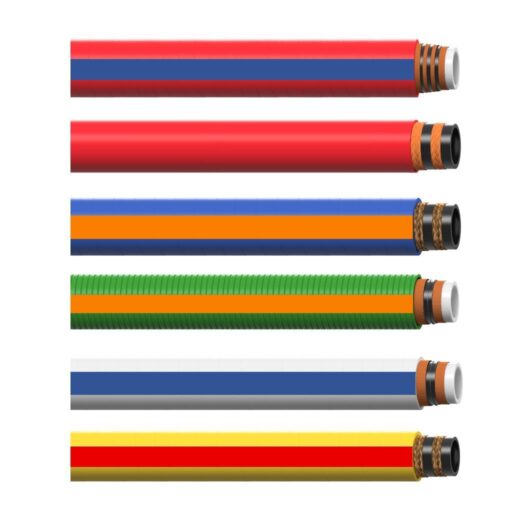

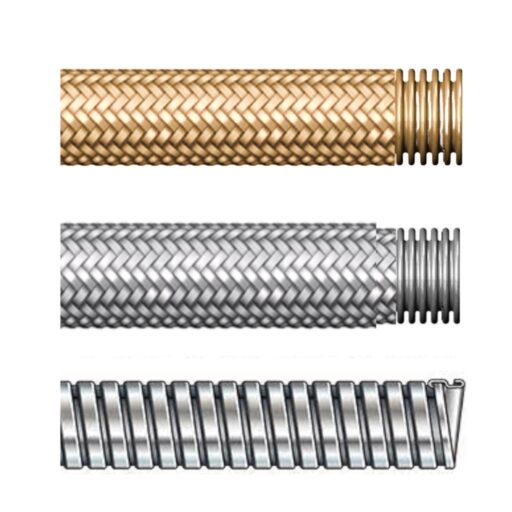

Our team understands that industrial hoses are mission-critical components across a wide range of industries, which is why we specialize in providing a comprehensive selection of solutions, including food-grade hoses, chemical transfer hoses, water suction and discharge hoses, compressed air hoses, steam hoses, and more. Whether you need a single hose or a large-scale order, we have the equipment, expertise, and streamlined infrastructure to meet your exact specifications.

Backed by an extensive inventory, cutting-edge crimping technology, and strategically located facilities, Shipyard Supply Inc. ensures fast, dependable service to minimize downtime and keep your operations running smoothly. When you choose Shipyard Supply Inc., you’re choosing a partner committed to quality, speed, and reliability—delivering high-performance hoses on time, every time.

Industry Leader in Industrial Hose Production

Why Crimping Is the Superior Choice for Industrial Hoses

When it comes to securing industrial hoses, two primary methods are used: crimping and clamping. While both have their place, crimping is the superior choice for industrial, hydraulic, and high-pressure applications due to its unmatched strength, reliability, and long-term durability. A properly crimped hose provides a leak-proof, secure connection, ensuring maximum safety and efficiency in demanding environments.

Why Choose Crimping Over Clamping?

✔ Stronger & More Secure Connection – Crimping evenly compresses the metal ferrule around the hose fitting, creating a tight, uniform seal that resists leaks, blow-offs, and failures even under extreme pressure.

✔ Enhanced Safety – Crimped hoses are far less likely to loosen or detach, significantly reducing the risk of accidents in high-pressure environments such as hydraulic systems, industrial fluid transfer, and chemical transport.

✔ Superior Durability – Unlike clamps, crimped connections excel in vibration-heavy, high-temperature, and chemically harsh conditions, ensuring long-lasting performance without the risk of loosening over time.

✔ Leak Prevention – Clamps rely on manual tightening and can loosen due to pressure fluctuations, movement, or temperature changes. Crimped fittings form a permanent, factory-quality seal, minimizing costly maintenance and downtime.

✔ Precision & Customization – Crimping allows for exact pressure ratings and hose sizes, ensuring a consistent, high-quality connection tailored to the specific application.

✔ Industry Compliance – Many industries, including marine, oil & gas, food processing, pharmaceuticals, and chemical transport, require crimped hose assemblies to meet strict safety and performance standards.

When to Use Clamping Instead of Crimping

While crimping is the gold standard, clamping may still be an option in select situations, such as:

Low-pressure applications where minor adjustments may be needed.

Temporary or emergency repairs requiring a quick fix.

Non-critical hose assemblies where pressure and safety regulations are less stringent.

FAQs About Hose Crimping

✅ What is hose crimping?

Hose crimping is a precision process that permanently secures a hose fitting using a hydraulic or pneumatic crimping machine. The machine compresses a metal sleeve (ferrule) over the hose and fitting, creating a strong, leak-proof connection.

✅ How does crimping compare to traditional hose clamping?

Crimping delivers a stronger, more reliable, and permanent connection, whereas clamps require manual tightening and may loosen over time, increasing the risk of leaks and failures.

✅ Which industries require crimped hoses?

Crimping is essential in industries such as marine, shipbuilding, oil & gas, hydraulics, manufacturing, food and beverage processing, pharmaceuticals, and chemical transport, where safety, precision, and high performance are critical.

✅ Can crimped hoses be reused?

No, crimped hoses are designed as a one-time assembly. If a hose needs replacing, a new hose and fitting must be crimped to ensure proper function and safety.

At Shipyard Supply Inc., we specialize in large-bore hose crimping and high-volume production, ensuring fast turnaround times and industry-leading quality. Contact us today to learn how our crimping expertise can keep your operations running safely and efficiently!