In industrial applications, it is essential to maintain a warm working environment to ensure the comfort and safety of employees. The temperature of a workspace can also impact productivity and equipment performance. One of the best ways to keep a workspace warm is through the use of high-quality heater ducting. In this article, we’ll explore the benefits of using high-quality heater ducting in industrial applications, the types of ducting available, how to choose the right ducting for your needs, and how to maintain it.

Benefits of High-Quality Heater Ducting

- Energy Efficiency

One of the primary benefits of using high-quality heater ducting is energy efficiency. Inferior ducting can result in heat loss and energy waste. High-quality ducting, on the other hand, is designed to minimize heat loss and maximize energy efficiency. By using high-quality ducting, you can save on energy costs and reduce your carbon footprint.

- Increased Comfort

Maintaining a comfortable temperature in the workspace is crucial to ensure the health and well-being of employees. High-quality heater ducting can help maintain a consistent temperature throughout the workspace, eliminating cold spots and drafts. This creates a more comfortable working environment, resulting in better morale and productivity.

- Improved Air Quality

In addition to maintaining a comfortable temperature, high-quality heater ducting can also improve air quality. Poor ducting can result in stagnant air, which can lead to an accumulation of pollutants and allergens. This can increase the chances of respiratory illnesses, which can lead to employee absenteeism and reduced productivity. High-quality ducting can prevent the accumulation of pollutants and allergens, resulting in better air quality and a healthier workspace.

- Enhanced Safety

Inferior ducting can also be a fire hazard, particularly if it is made from flammable materials or is improperly installed. High-quality heater ducting, on the other hand, is designed with safety in mind. It is made from non-flammable materials and is installed in a way that reduces the risk of fire. This can protect employees and equipment and prevent costly downtime due to accidents.

Types of High-Quality Heater Ducting

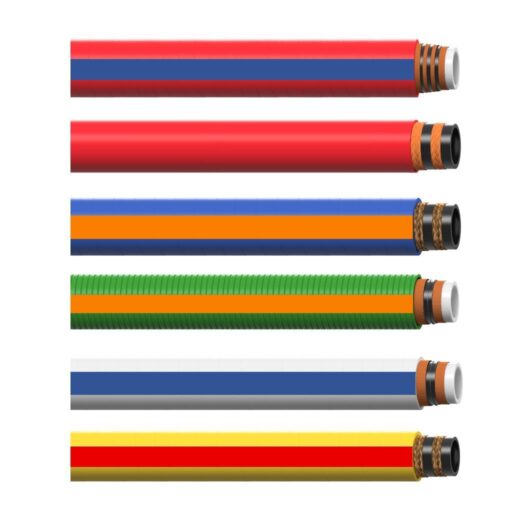

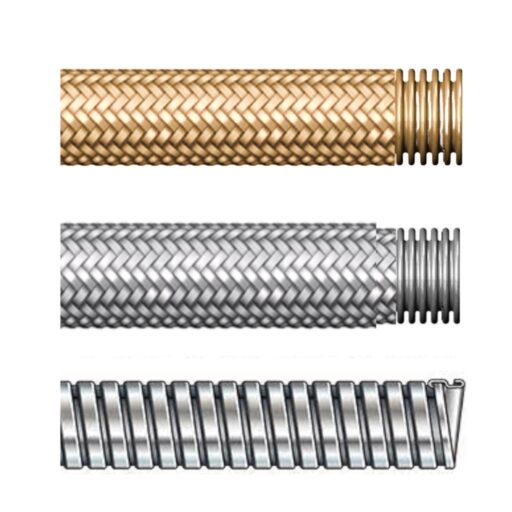

- Materials

There are several materials used in high-quality heater ducting, including PVC, aluminum, and stainless steel. PVC ducting is affordable, lightweight, and easy to install, making it an excellent choice for some applications. Aluminum ducting is durable, corrosion-resistant, and can handle high temperatures, making it suitable for many industrial applications. Stainless steel ducting is the most durable option, with excellent resistance to corrosion and high temperatures. It is also the most expensive option.

- Insulation

Insulation is another critical consideration when selecting high-quality heater ducting. Insulated ducting can help reduce heat loss and improve energy efficiency. There are several types of insulated ducting, including fiberglass, foam, and reflective insulation. Fiberglass insulation is the most common type used in ducting. It is affordable, easy to install, and provides excellent thermal insulation. Foam insulation is another option, providing better insulation than fiberglass but at a higher cost. Reflective insulation is a third option, providing the highest level of insulation but at a higher cost than both fiberglass and foam.

Choosing the Right High-Quality Heater Ducting

Choosing the right high-quality heater ducting for your application requires careful consideration of your needs. You must determine the size of your workspace, the type of equipment used, the temperature requirements, and the budget. Consulting an expert can help ensure that you select the right ducting for your needs. Additionally, there are several factors to consider when choosing high-quality heater ducting, such as the length and diameter of the ducting, the type of material and insulation used, and the airflow requirements. It is essential to select ducting that can handle the temperature requirements of your application, as well as any potential hazards, such as chemicals or moisture.

Maintaining High-Quality Heater Ducting

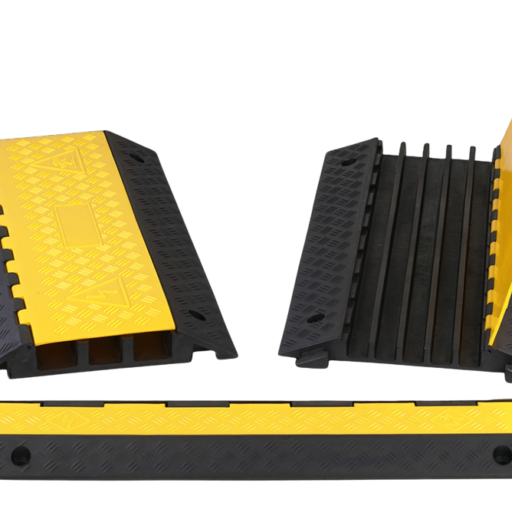

Once you have installed high-quality heater ducting, it is essential to maintain it properly to ensure its longevity and performance. Regular inspections and cleanings can help prevent issues such as blockages and leaks, which can lead to reduced efficiency and safety hazards. It is also essential to address any damage or wear and tear promptly, as this can compromise the integrity of the ducting and increase the risk of safety hazards.

Conclusion

High-quality heater ducting is a critical component of maintaining a warm and comfortable workspace in industrial applications. By using high-quality ducting, you can increase energy efficiency, improve air quality, enhance safety, and ensure the comfort and productivity of employees. When selecting high-quality heater ducting, it is essential to consider factors such as materials, insulation, and airflow requirements. Proper maintenance is also crucial to ensure the longevity and performance of the ducting. By investing in high-quality heater ducting and proper maintenance, you can create a safer, more comfortable, and more productive workspace for your employees.

Want to find out more? Visit us at Shipyard Supply!