Potable water hoses are specially designed hoses used for conveying clean and safe drinking water. These hoses are made of materials that are safe for human consumption and are designed to prevent contamination of the water being conveyed.

Importance of safe drinking water on the go

Access to safe drinking water is essential for maintaining good health and preventing waterborne diseases. Many people, particularly those who travel frequently or work in the food and beverage industry, rely on access to clean and safe drinking water while on the go.

Contaminated water can contain harmful bacteria, viruses, and other pathogens that can cause a range of health problems, from minor gastrointestinal issues to more serious illnesses. In the food and beverage industry, contaminated water can also pose a risk to consumers if it is used in the production or preparation of food and beverages.

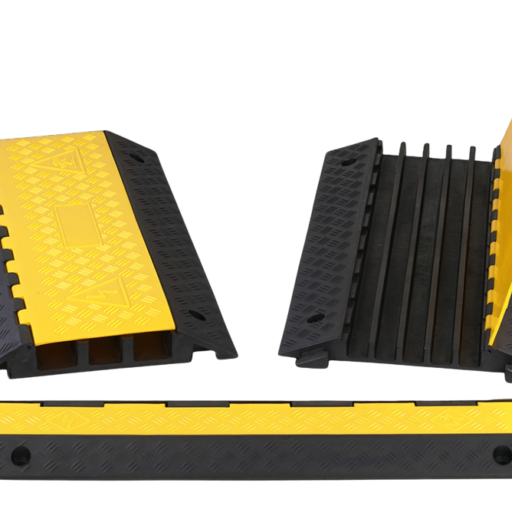

Ensuring safe drinking water on the go requires a combination of measures, including using potable hoses made from safe materials, regularly cleaning and maintaining these hoses, and following relevant regulations and industry standards. By prioritizing safe drinking water, individuals and businesses can help protect themselves and others from the risks of contaminated water and promote better health and well-being.

Significance of water hoses in the food and beverage industry

The food and beverage industry requires a reliable supply of safe drinking water for various operations, such as food preparation and cleaning. Potable water hoses play a crucial role in ensuring that the water used in these operations is clean and safe for human consumption. Failure to use potable hoses can result in contamination of the water, which can lead to serious health risks and legal liabilities for businesses.

The Importance of Safe Drinking Water

Health risks associated with contaminated water

- Contaminated water can cause a range of health issues, including gastrointestinal illnesses, skin infections, and respiratory problems.

- Contaminated water can cause waterborne illnesses, such as diarrhea, nausea, vomiting, abdominal cramps, fever, and fatigue.

- Waterborne illnesses can be caused by harmful bacteria, viruses, and other pathogens present in contaminated water.

- Vulnerable populations such as children, the elderly, and those with weakened immune systems are at greater risk of developing serious health complications from waterborne illnesses.

- Contaminated water can also contain harmful substances like chemicals and heavy metals, which can accumulate in the body and pose additional health risks.

- Drinking contaminated water can lead to both short-term and long-term health effects, depending on the severity and duration of exposure.

The need for clean drinking water in the food and beverage industry

Clean drinking water is essential in the food and beverage industry to ensure the safety and quality of the products being produced and served. The food and beverage industry is responsible for providing safe and healthy food and beverages to consumers, and clean drinking water plays a crucial role in this industrial ductwork process.

Water is used in a variety of ways in the food and beverage industry, including as an ingredient in products, for cleaning and sanitizing equipment and facilities, and for general food and beverage preparation. If the water used in these processes is contaminated, it can lead to the contamination of the final product and pose a risk to consumer health.

The role of water hoses in ensuring safe drinking water

Potable hoses play a critical role in ensuring safe drinking water in the food and beverage industry. These hoses are designed specifically for use with drinking water and are made from materials that are safe for human consumption.

- Potable hoses help to prevent the contamination of drinking water by ensuring that the water is transported through a clean, safe, and dedicated system. This helps to minimize the risk of harmful bacteria, chemicals, and other contaminants being introduced into the water supply.

- In addition to ensuring the safety of drinking water, potable water hoses also help to maintain the quality of the water being transported. This is particularly important in the food and beverage industry, where the taste, appearance, and texture of products can be affected by impurities in the water.

- They are also designed to be easy to clean and maintain, which is essential for ensuring their continued effectiveness in delivering safe and clean drinking water. Regular cleaning and maintenance of these hoses help to prevent the buildup of harmful bacteria and other contaminants.

Types of Potable Water Hoses

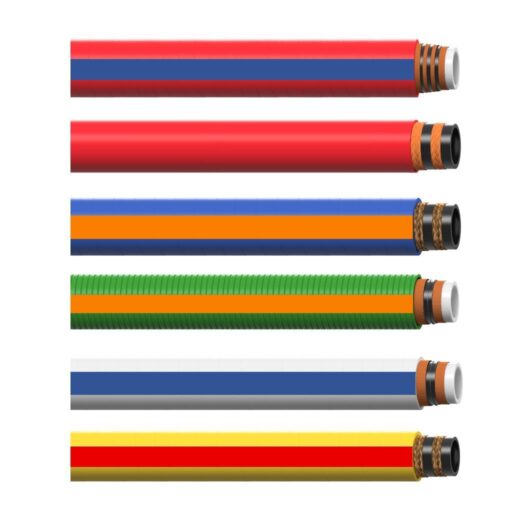

There are several types of potable hoses available for use in the food and beverage industry, each with its own set of advantages and disadvantages. Some of the most common types of potable hoses include:

- PVC hoses: PVC (polyvinyl chloride) hoses are a popular choice for potable water applications due to their affordability and versatility. They are lightweight, flexible, and easy to handle, making them suitable for a variety of applications. However, they can be prone to kinking and are not as durable as some other materials.

- Rubber hoses: Rubber hoses are a more durable option for potable water applications. They are resistant to abrasion, tearing, and punctures, making them ideal for heavy-duty applications. However, they can be heavy and less flexible than PVC hoses.

- Thermoplastic hoses: Thermoplastic hoses are lightweight and flexible option that is resistant to kinking and crushing. They are also resistant to chemicals and UV radiation, making them suitable for outdoor use. However, they are less durable than rubber hoses and may not be suitable for heavy-duty applications.

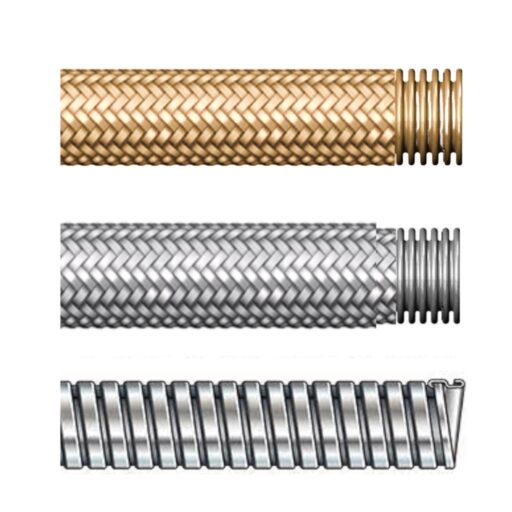

- Stainless steel hoses: Stainless steel hoses are a durable and corrosion-resistant option for potable water applications. They are suitable for high-temperature and high-pressure applications and are ideal for use in areas where cleanliness is critical. However, they can be heavy and more expensive than other materials.

Factors to consider when choosing a potable water hose

When choosing a potable water hose for use in the food and beverage industry, there are several factors to consider to ensure that the industrial ductwork is safe, effective, and durable. Some of the key factors to consider include:

- Material: Different materials, such as PVC, rubber, thermoplastic, or stainless steel, offer varying levels of durability, flexibility, and resistance to chemicals and other contaminants.

- Size and length: The size and length of the hose should be appropriate for the intended use and the available space.

- Temperature range: The hose should be able to withstand the temperatures it will be exposed to during use, whether high or low.

- Pressure rating: The hose should be rated to handle the maximum pressure it will be exposed to during use.

- Compliance with regulations: The hose should meet industry standards and regulations for potable water safety, such as those set by the FDA, NSF, and other regulatory bodies.

- Fittings and connections: The hose should have appropriate fittings and connections to ensure a secure and leak-free connection to the water source and the equipment it will be used with.

- Certification: It may be beneficial to choose a hose that is certified by a reputable third-party organization to ensure its safety and quality.

Maintenance and Cleaning of Potable Water Hoses

Regular maintenance and cleaning of potable hoses are essential for ensuring that they remain safe and effective for use in the food and beverage industry. Here are some key considerations for maintaining and cleaning potable hoses:

- Regular inspection: Hoses should be visually inspected before and after each use to check for any signs of damage or wear that could compromise their safety or effectiveness.

- Proper storage: Hoses should be stored in a clean, dry area away from direct sunlight and sources of heat, which can cause damage or degradation.

- Cleaning procedures: Hoses should be cleaned regularly using appropriate cleaning procedures, which may vary depending on the type of hose and its intended use. For example, some hoses may require only a simple rinse with clean water, while others may require more extensive cleaning with soap or other cleaning agents.

- Disinfection: In addition to regular cleaning, hoses should also be disinfected regularly to kill any bacteria or other microorganisms that may be present. Disinfection can be done using a variety of methods, such as soaking the hose in a disinfectant solution or using a special cleaning device that includes a disinfection step.

- Replacement: Hoses should be replaced periodically based on their condition and frequency of use. Over time, hoses can become worn or damaged, which can compromise their safety and effectiveness.

Regulations and Standards

There are various regulations and standards that govern the manufacture, use, and maintenance of potable hoses in the food and beverage industry. Some of the key regulations and standards include:

- FDA regulations: The U.S. Food and Drug Administration (FDA) has specific regulations governing the use of potable hoses in the food and beverage industry. These regulations specify the materials that can be used in making hoses, as well as the testing and labeling requirements that must be met.

- NSF/ANSI standards: The National Sanitation Foundation (NSF) has developed a set of standards known as NSF/ANSI 61 that are designed to ensure that potable water hoses are safe and effective for use in the food and beverage industry. These standards cover a range of criteria, including materials, construction, and performance.

- European regulations: In Europe, potable hoses are subject to regulations set forth by the European Union (EU). These regulations cover a range of criteria, including materials, testing, and labeling.

- Industry standards: There are also various industry-specific standards that may apply to the use of potable hoses in specific sectors of the food and beverage industry. For example, the dairy industry has specific requirements for hoses used in milk processing.

Complying with these regulations and standards is important for ensuring that potable hoses are safe and effective for use in the food and beverage industry. Businesses should work with reputable suppliers who can provide hoses that meet these regulations and standards, and should also implement appropriate maintenance and cleaning procedures to ensure ongoing compliance.

Conclusion

Potable hoses are essential for ensuring safe drinking water in the food and beverage industry. Contaminated water can pose serious health risks to consumers, and using potable hoses made from safe, food-grade materials can help prevent contamination.

It is important for businesses to prioritize safe drinking water and to invest in high-quality, food-grade potable hoses. By doing so, businesses can help protect consumers and ensure that their products meet industry standards and regulations.

Potable hoses play a critical role in ensuring clean drinking water on the go, particularly in the food and beverage industry. By choosing the right materials, following appropriate maintenance and cleaning procedures, and complying with relevant regulations and standards, businesses can help ensure that their potable water hoses remain safe and reliable for human consumption.

Want to find out more? Visit us at Shipyard Supply!